Wayyyy back in my freshman year (yes, I'm just a Junior) I joined one of our ASME teams preparing an exhibit for Engineering Open House (EOH) 2024. The goal was to create a drone that was controlled by tilting, lifting, and turning your hand. Additionally, with the push of a button, a remote-controlled claw device would pick up an item underneath the floating drone, and would drop it upon releasing the button. From what you've read so far, I'm sure you can guess what part of the project I was on. Overall, this project was very fun and I learned a lot about electrical circuits, PWM and servo motors, RF signals, electrical housing, and designing for assembly.

Electronics

When creating an attachment for a flying drone, the first consideration is weight. Upon first receiving the drone, we strapped weights to the bottom and tested its flight time with each weight, finding that it could fly consistently with no more than a 60g payload. With so little wiggle room, we decided that the objects it picked up must be incredibly light - say about 10g. This left my claw team with 50g to work with.

Obviously, this meant that we couldn't fit a battery in our mechanism, meaning that it would have to draw power directly from the drone's lipo battery pack. The other problem that this created was that we didn't have access to a microcontroller that could run off the 3.7V battery, and even if we did, it would likely drain it extremely quickly. We obviously needed a motor to actuate the claw, so a 9g servo was really the only option. Unfortunately, most of the time these are run through PWM signals generated by an Arduino library, but we didn't have a microcontroller.

The solution? Connect the signal pin directly to an RF receiver and transmit a custom PWM signal over radio. That way, there was no need for a microcontroller onboard the drone but the servo motor could still be actuated to the correct position. This created two circuits: the receiver circuit and the transmitter circuit.

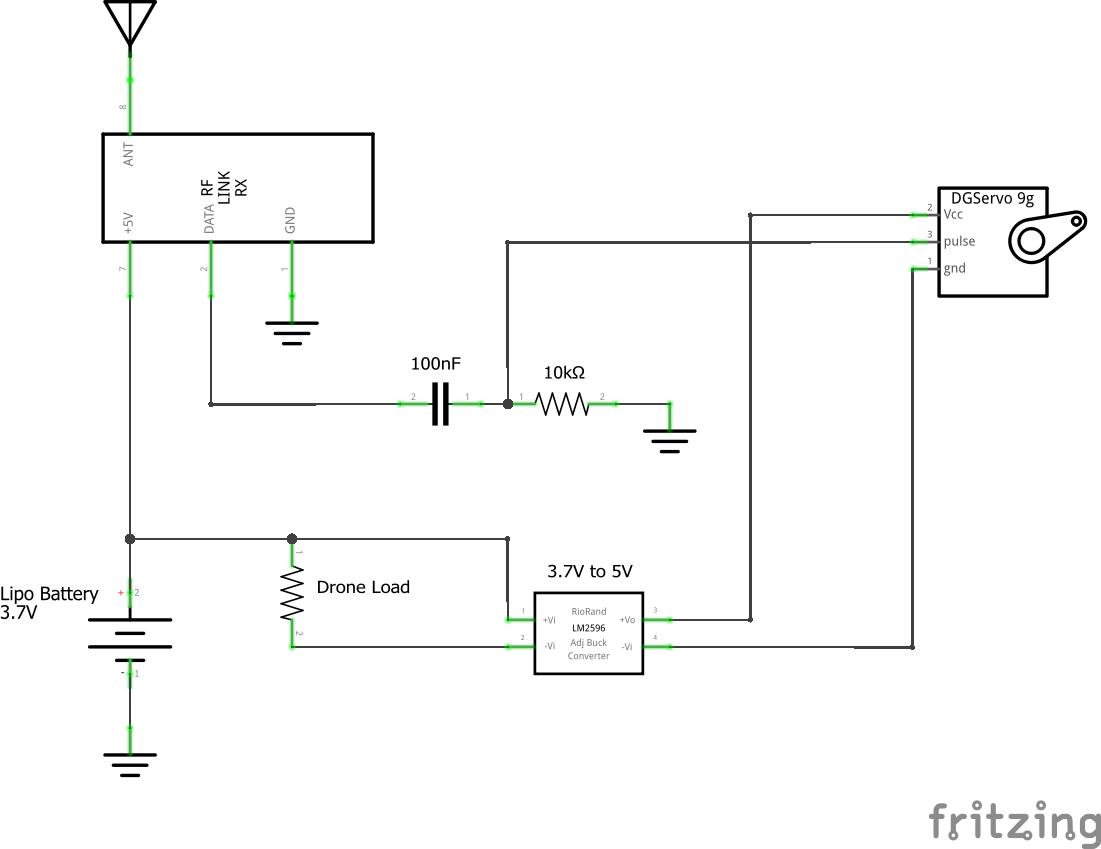

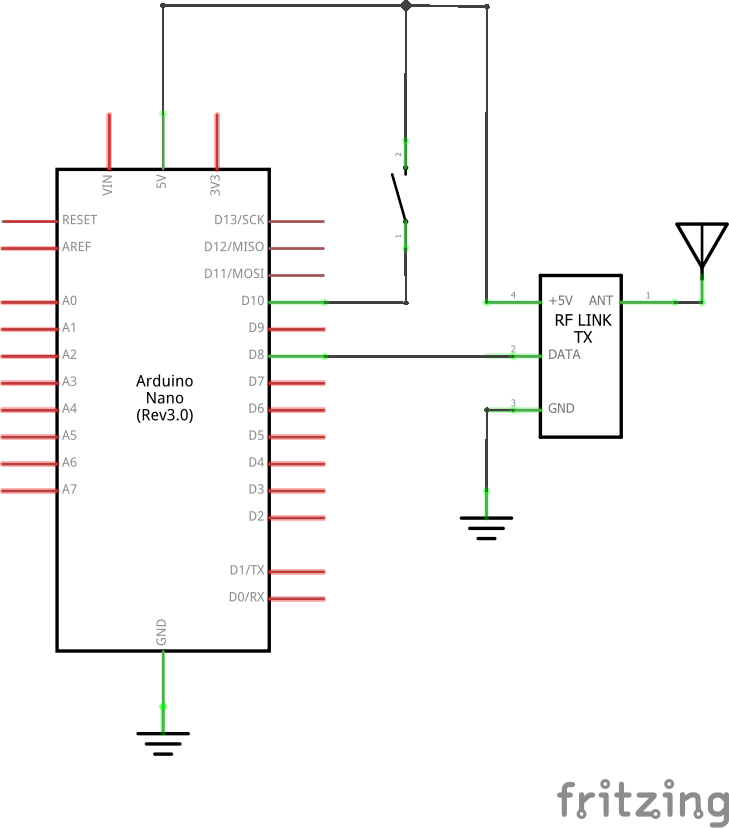

The receiver consisted of an RF receiver, high-pass filter, a servo motor, and spliced power and ground from the lipo battery. The transmitter then had an Arduino Nano connected to a button circuit and RF transmitter. It was designed such that it would transmit one PWM frequency while the button was not pressed - corresponding to the "open" position for the servo - and another "closed" frequency while the button was pressed. These frequencies were then read by the receiver and thereby the Servo, causing claw actuation.

Electrical Schematics

Receiver Circuit

Transmitter Circuit

Mechanical Design

While my primary contribution was circuit design and implementation, I also designed the electrical housing and drone body interface. This box at the top of the claw mechanism can be seen clearly in the figure on the right. Since this claw attachment directly replaced the drone battery cover attachment, some main design considerations included snap fits to properly interface with the body, screwhole mounts for the servo motor, a multi-layered approach to properly fit all electronics under the body of the drone and maintain proper center of mass, a hole for the receiver antenna, a hexagonal mesh for weight reduction, and a small cover for the wires that splice into the drone battery supply.

The claw mechanism was designed by another member of the team, but we all had input into the initial design criteria, which included a large surface area to facilitate the easy grabbing of various types of items. Additionally, this double-rocker linkage system underwent many iterations to properly define the range of motion from the motor to the external arms.

As you can see, this claw was fully functional with remote control. It is spliced into the drone battery supply and has been programmed for a full range of motion upon actuation. At the end of the day, and after dozens of iterations for weight-optimization, the entire claw mechanism (without the battery) came out to 46g, which was enough for us to have sustained flight for 30min.